As a manufacturer of high quality edible fats, ALVA FOOD makes a strong daily commitment to guaranteeing the safety of its customers and to control the impact of its activity on the environment.

Certifications

The ALVA FOOD production site, based in Rezé (Loire-Atlantique), is exclusively dedicated to food production.

Its activity is controlled and secured by many standards and certifications, both in terms of continuous improvement of processes and to meet regulatory requirements and respect for the environment.

The "Origine France Garantie"

label certifies the French origin of our animal-based raw materials.

Download PDF

RSPO

(Roundtable Sustainable Palm Oil) guarantees the company's support to the production of sustainable palm oil.

RSPO Membership Number: 2-0158-10-000-00

Sedex commitment

international ethical, social and environmental certification of the company's best practices.

Download PDF

BRC GS

The BRCGS Food Safety Global Standard is the most widely accepted food safety standard in the world.

Download PDFTraceability and food safety

Traceability and food safety are fully integrated into our manufacturing process.

The traceability of incoming and outgoing flows is tracked by rigorous documentary and computer monitoring, regularly and randomly tested by the authorities, our customers and our own quality department. For our partners, this guarantees reliable, controlled and certified products.

The food safety of our products is guaranteed by:

- An in-house laboratory which conducts tests at all phases of production

- Several external laboratories (ITERG, EUROFINS and INOVALYS, etc.) which perform random checks

- Suppliers audits and raw material checks

- A quality team directly in the field which works closely with the production team and process

- Training in manufacturing processes, conducted twice a year with staff dedicated to production

- Test tubes on gray background

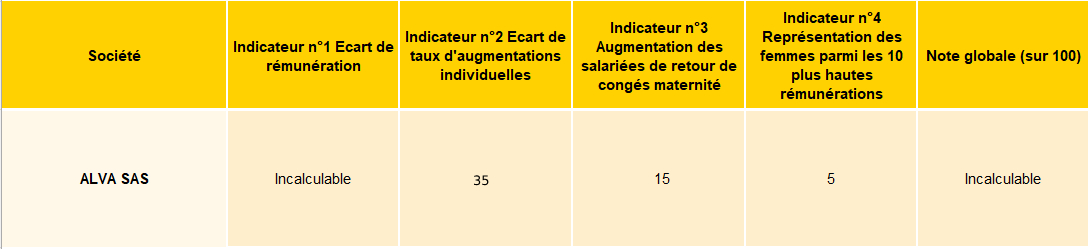

Equality between Women and Men

is at the heart of our company’s concerns, which is committed on a daily basis to promoting diversity, guaranteeing professional equality between the sexes and fighting against all forms of discrimination. Find below the results of the Gender Equality Index for the year 2024:

Respect for the environment

We attach great importance to controlling our environmental impact. Within this context, ALVA FOOD’s QHSE team (Quality, Health, Safety, Environment) controls and ensure that all of our commitments are respected.

Respect for neighbours

Acoustic panels are positioned on eternal installations and ALVA employees are aware of the importance of noise control.

Air quality control

The air from the process is first treated then sent to a bio-filter made of coconut fibre and peat. 40,000 m3 of air is treated every hour.

ISCC

After analysis, if a fat does not meet our specifications, it is sent to the bio-fuel division or to our partner Oléo Recycling. This is why ALVA has been granted ISCC certification (International Sustainability and Carbon Certification)

Recycling

Cardboard boxes, glass, wood, plastics, aerosols, cloth and gloves are sorted.

Water treatment

All water used in the process is treated in our purification station. ALVA regularly monitors the waste water, conducting over 1,800 analyses per annum.

The mud is an organic fertiliser and is spread over the fields. Thanks to its composition, it does not reach the groundwater. The rest of the mud is methanised to produce electricity.